Selecting the correct blade size is essential for achieving clean, efficient cuts in stone, tile, or masonry projects. Different diameters cater to specific tasks, balancing precision, power, and material compatibility. Below, we explore common blade sizes and their ideal applications.

Blade Sizes and Applications

4–6 Inches:

Materials: Ceramic tiles, glass mosaics, thin marble.

Use Cases:

Trimming edges for bathroom or kitchen backsplashes.

Cutting intricate patterns in decorative stone inlays.

Tools: Handheld angle grinders or compact tile saws.

7–10 Inches:

Materials: Granite countertops, thick porcelain tiles, limestone.

Use Cases:

Shaping slabs for kitchen islands or tabletops.

Cutting large-format tiles for flooring installations.

Tools: Mid-sized wet saws or bridge saws.

12+ Inches:

Materials: Reinforced concrete, dense quartzite, industrial composites.

Use Cases:

Quarrying stone blocks for architectural projects.

Cutting thick pavers for outdoor landscaping.

Tools: Heavy-duty industrial saws or hydraulic rigs.

Key Selection Tips

Wet vs. Dry Cutting: Water-cooled blades reduce heat and dust for polished finishes.

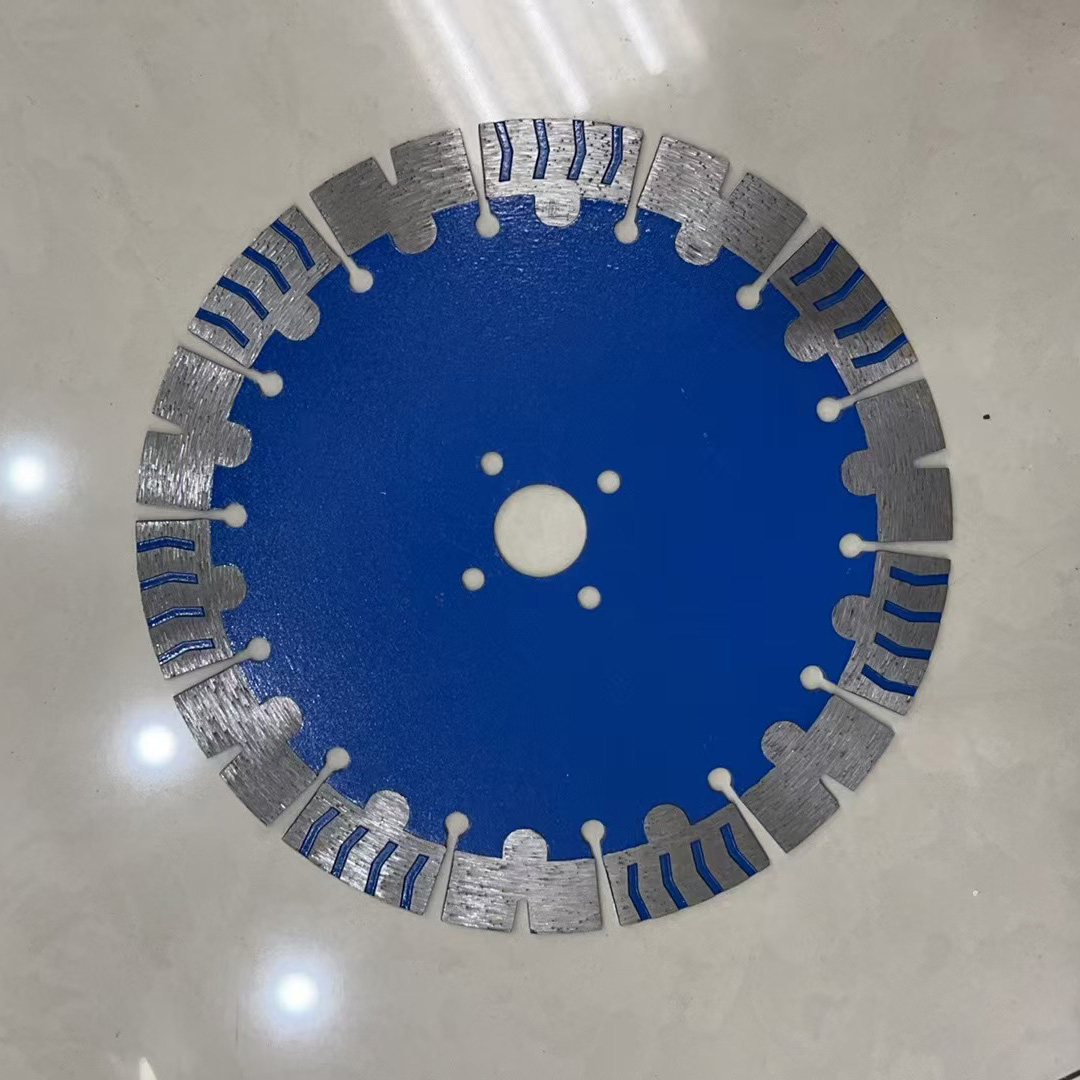

Segmented vs. Continuous Rim: Segmented blades handle rough cuts in concrete; continuous rims excel in delicate materials.

Blade Thickness: Thin blades (2–3mm) minimize material waste in expensive stone.

Need a Precision Diamond Cutting Blade?

Contact us for expert guidance:

WhatsApp: +86 151 3848 6891

Email: henanxingchuanyi@outlook.com

Phone: +86 151 3848 6891